The Cannabis Trimmer Perfected.

Quality & Control

Top-Shelf Bud Starts With GreenBroz Trimmers

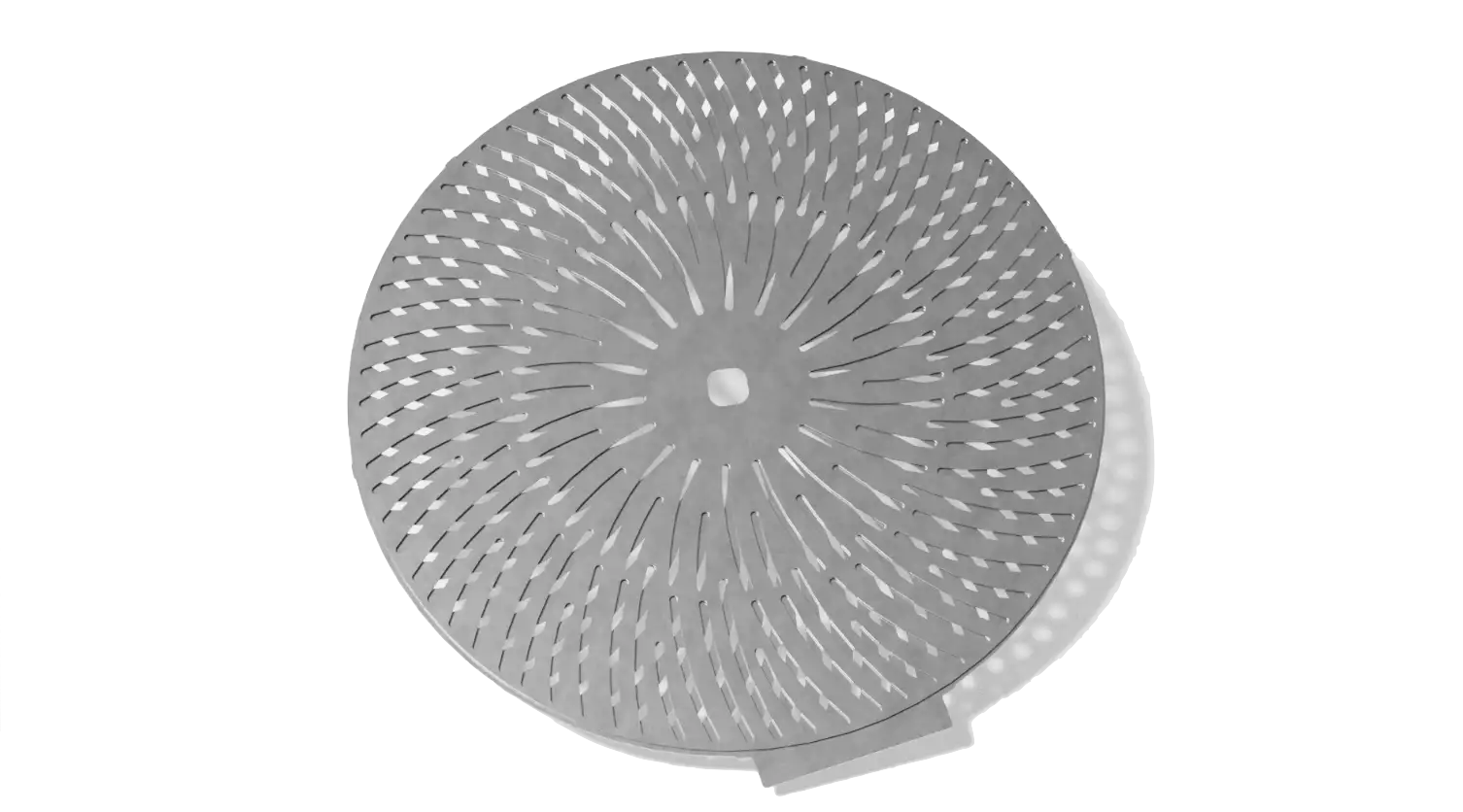

Patented Trimming Blades

Our patented rotating top blade gently integrates cannabis and hemp buds while trimming off excess leaves and material.

Wash Down Ready Stainless Steel

Pressure wash the food safe stainless steel for faster cleaning in between batches of resinous buds.

Quiet Controlled Trimming

No vacuums or tumble chambers, keeping your ears and trichomes safe.

Suggested Size:

Max Processing:

Dimensions:

Suggested Size:

Max Processing:

Dimensions:

Suggested Size:

Max Processing:

Dimensions:

Suggested Size:

Max Processing:

Dimensions:

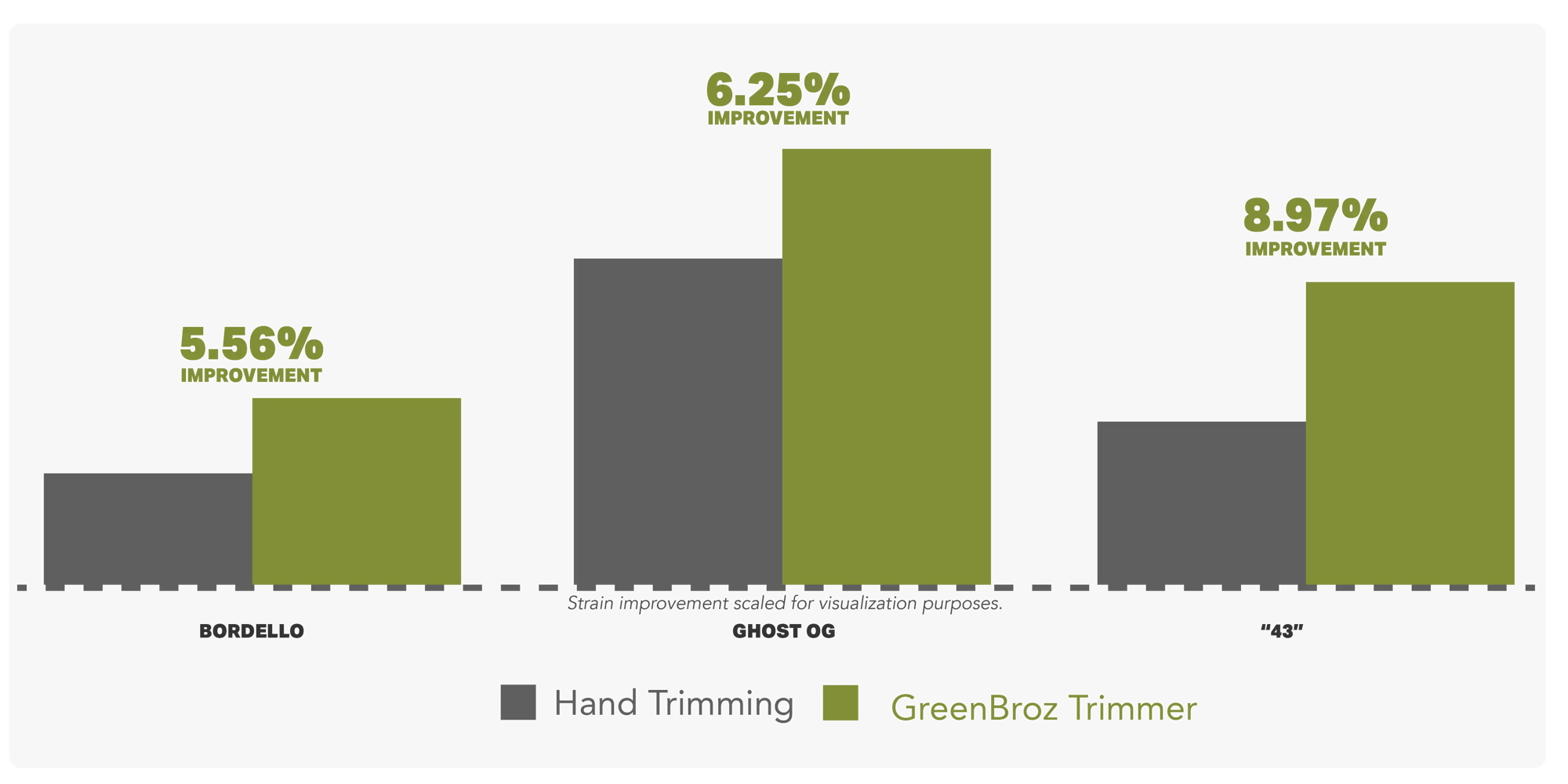

GreenBroz Trimmers Can Improve THC by 6.92%

In a direct hand-to-machine trimming comparison of cannabinoid content from 3 different strains, GreenBroz dry trimmers come out on top. Increasing THC/A on average by 6.92% over hand trimming the same strain.

See The Data

Enter your email below to download the data.

.webp?width=640&height=480&name=MicrosoftTeams-image%20(1).webp)

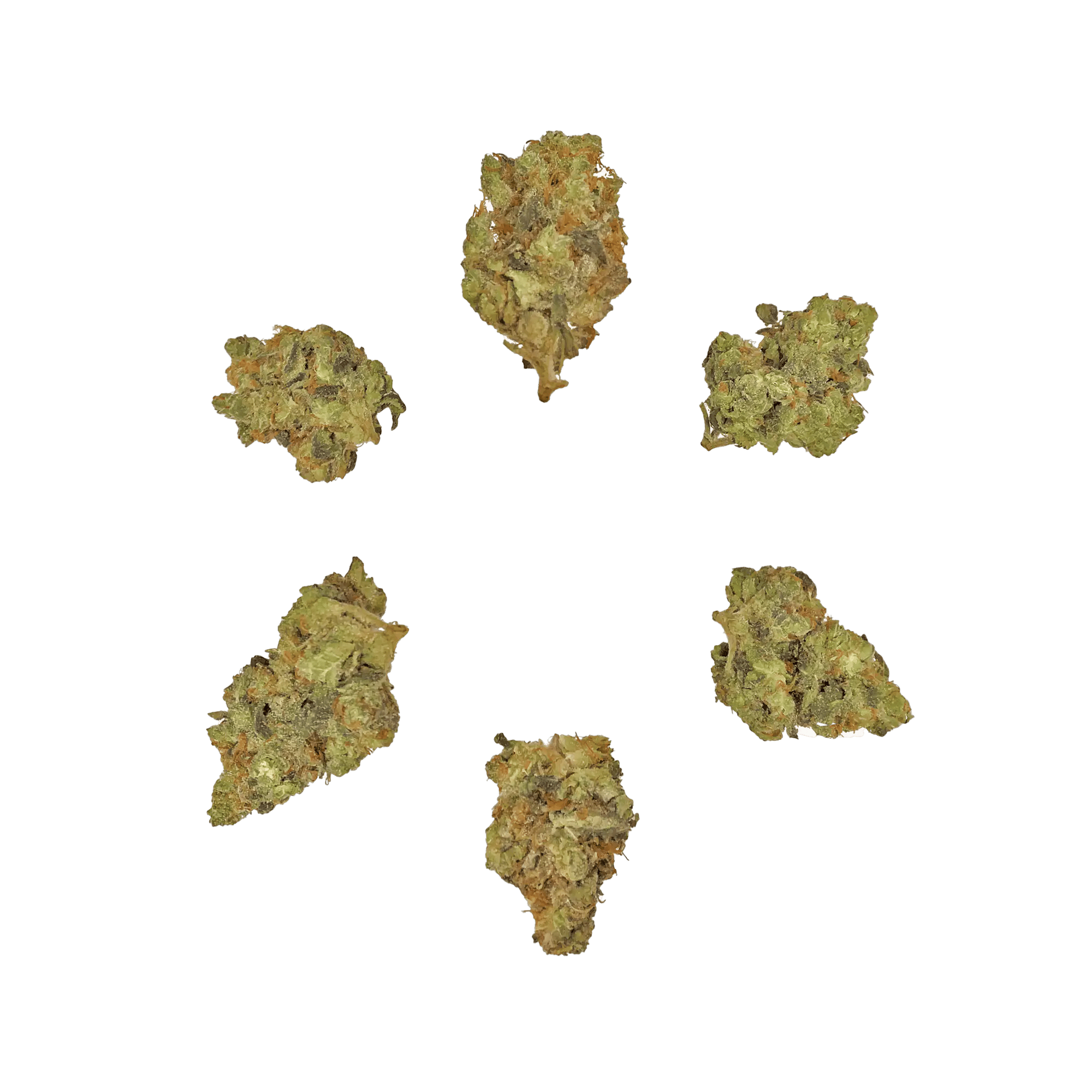

Gentle by Design

Trichomes, safe and sound

The top-loading and patented blade design on our trimmers, allows for the most gentle and controlled trimming of your buds.

Controlled

Total Trim Control

GreenBroz trimmers allow users to work with the trimming machine, controlling speed, direction, and overall trim level.

New!

Automatically link per-strain trimming recipes to real world batches enabling your facility to be more compliant and consistent.

Your Next Trimmer

We love our GreenBroz equipment! The quality of their equipment is excellent. Everything we have purchased has been reliable, easy to operate, and simple to maintain. They make our operation run smoother and more efficiently.

Faith Henderson

Production Manager | Phat Panda

We love our GreenBroz equipment! The quality of their equipment is excellent. Everything we have purchased has been reliable, easy to operate, and simple to maintain. They make our operation run smoother and more efficiently.

Faith Henderson

Production Manager | Sira Naturals Inc.

In the 40 years I've been in the industry, I've seen a lot of change. But the one thing that doesn't change is the need for quality partners to work with. People who care about your success as much as you do. GreenBroz is one of those companies. Made in the USA, Veteran-owned, they create a quality product that helps us as cultivators create a finished product that works in the market of today.

Kevin Jodrey

Cultivation Expert

Ready to elevate your harvest?

Reach out to dedicated team of experts and we'll be by your side the entire time, improving your cannabis cultivation.

The quality coming out at end was nice… it was better then hand trimmed. Our patients love it.

- Rick Redekop